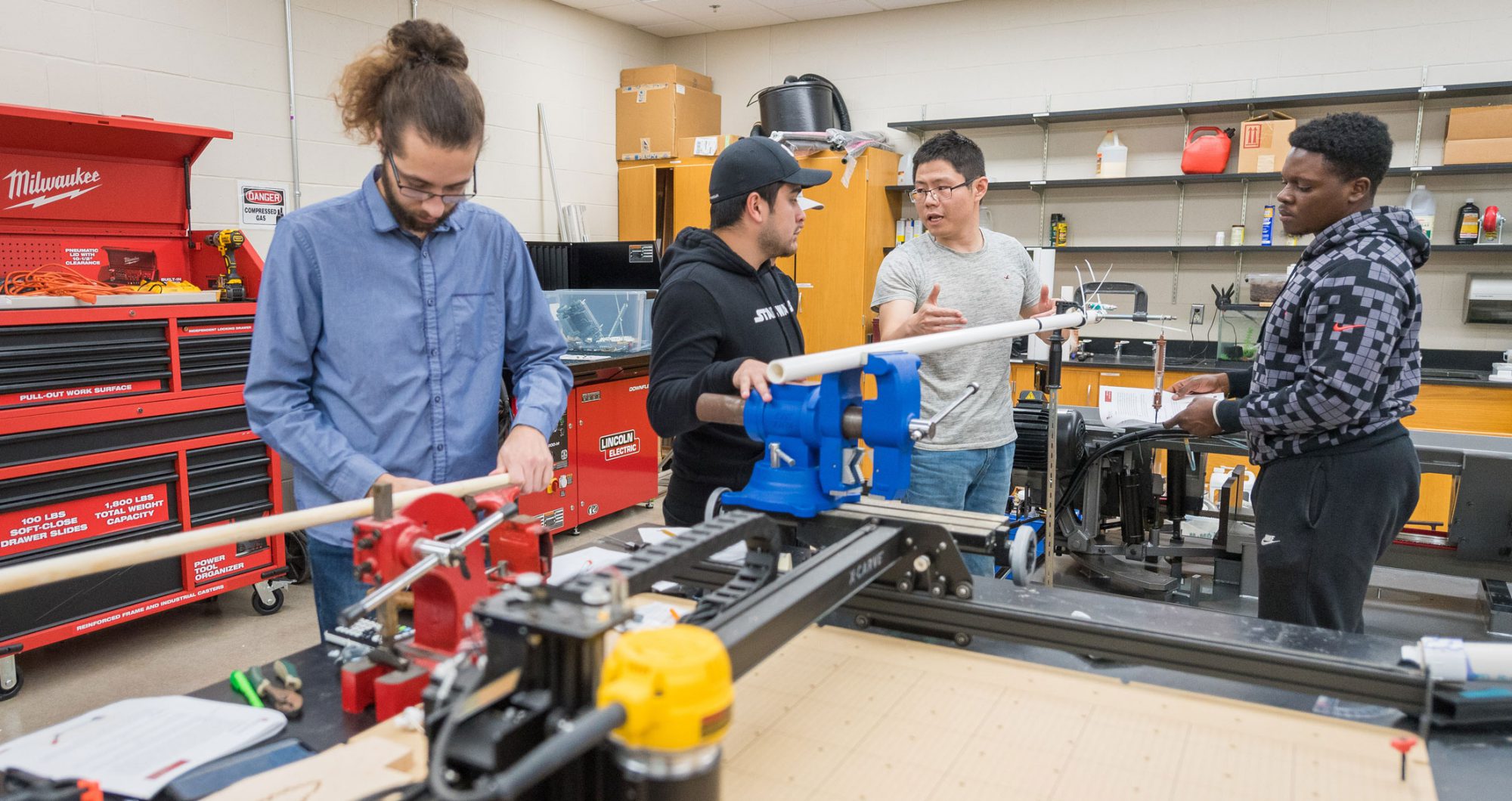

Maker-space open to more than just students in engineering

Photo by David Norris

Students Trace Edmondson (left) and Ethan Ernest and work on the new CNC (Computer Numerical Control) machine in the The Mast.

By Emeline Gullixson (’21) – Bethany Magazine, Winter 2023

Engineering sciences is one of Bethany’s fastest growing programs, and with that growth comes a need for additional accommodations–notably, The Mast, an open layout lab with updated technology in Meyer Hall. The name evokes a Viking ship’s mast, and the facility is propelling the program forward.

Recently constructed with help through a generous gift from the Minneapolis-based Graco Foundation, the space allows students hands-on experience with relevant engineering equipment. And, it has a promising future for expansion. Before its construction, Meyer Hall held a few, separate engineering labs. Now, The Mast is a cohesive combination of those labs on Meyer’s lower level. With a walkable, open layout, many students can work there at a time. A wide open space allows for students of different disciplines to work together, sharing ideas.

Photo by David Norris

The room with 3-D printers and the new CNC machine are separated by a wall with windows to look into a second room with more tools to work and build.

Inside The Mast is an engineering student’s playground: updated 3D printers, laser cutters, and a high-powered computer that can do complex computations, simulations, and calculations. They also have two CNC (Computer Numerical Control) machines, which are digital cutting tools. These machines are used for testing materials and electronics for a variety of engineering disciplines, such as physics and solid mechanics. There are also plenty of basic tools for cutting and drilling in the mechanics section.

Almost all engineering classes involve labs at one point or another, to supplement and apply what students are learning in the classroom. The Mast’s open layout and updated equipment ensures that Bethany students get the most practical, hands-on experience, and gives them an advantage for their future careers. Students are also encouraged to make use of the space outside of class, taking their time to work on projects. It is certainly big enough that many students can work there at a time.

Assistant Professor of Engineering Sciences Sheng Sang is one of the engineering professors at the forefront of The Mast’s continual development. Sang teaches and develops mechanical engineering classes while also planning The Mast’s future.

“Mechanical engineering is developing every year—new technology, new machines—so we have to update everything year by year,” said Sang.

Because engineering technology is constantly evolving, Sang will often place orders for new equipment to add to the already useful essentials inside The Mast. Teaching has given him a keen understanding of what equipment students will most benefit from. When a machine needs an update or the department has an idea for a new piece of equipment, he will purchase that equipment through grants—that is how they got their new CNC machine, for instance.

One of Sang’s goals is to make sure that students have the opportunity to become proficient in machines that they will be using in the field. The CNC machine is one such piece of equipment, which students already enjoy using. Often, engineering companies will look for keywords on an applicant’s resume, showing that the applicant has worked with a few different pieces of equipment and technology. Sang noted that any engineering company would expect their employees to know their way around a CNC machine—particularly mechanical engineers. Thankfully, Sang gets to see those needs up close while teaching.

“We have several different sizes of 3D printers, which really give students a leg up,” said Sang. “It’s a very basic tool for all mechanical engineers. No matter what company you go to, [engineering students] should know how to use that machine.”

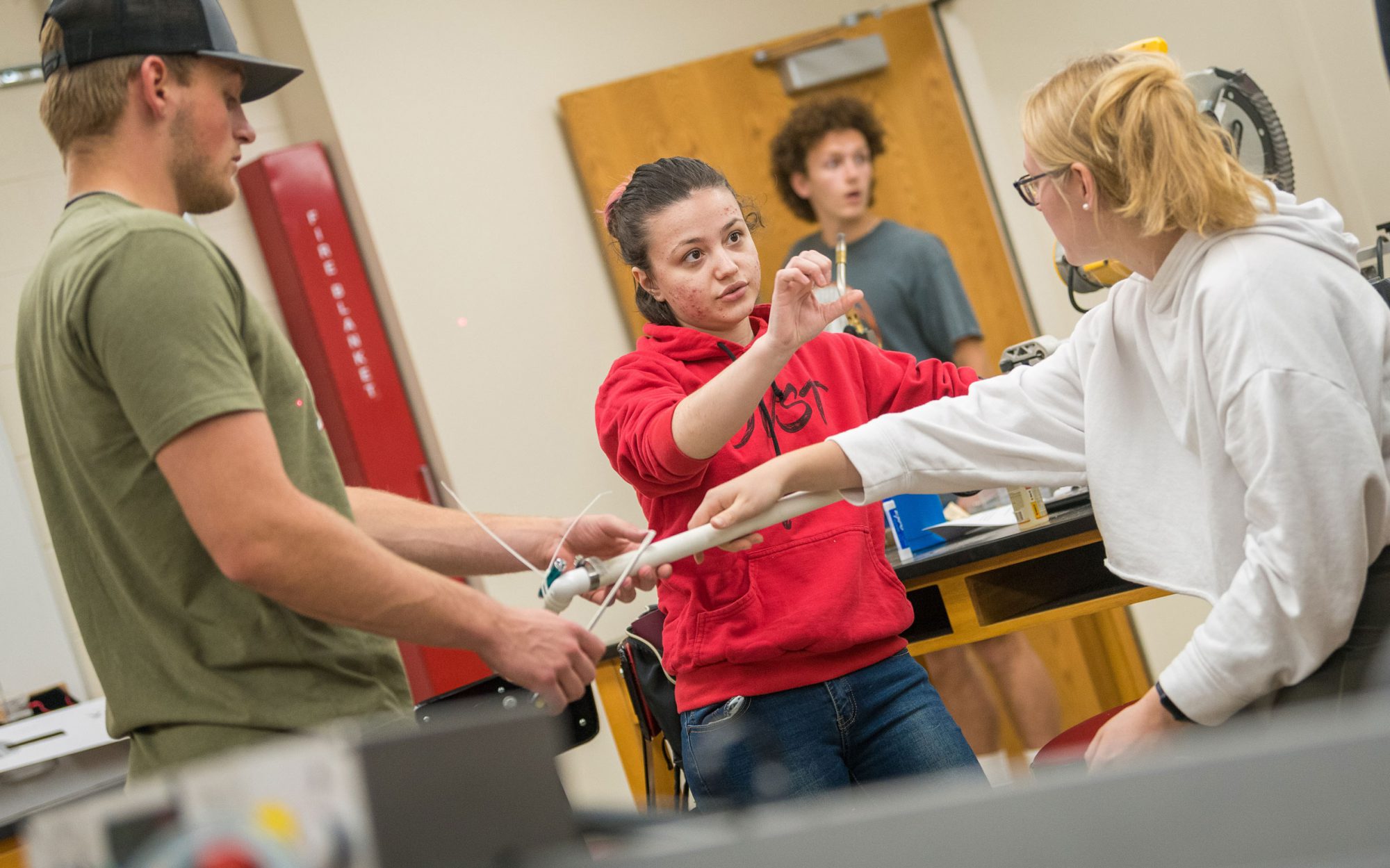

Photos by David Norris

During a recent class, students worked on measuring the shear modulus of different materials via torsion and laser technique.

It seems that living in the Midwest is an advantage for some engineering students. Sang was pleasantly surprised to learn that many of his native Midwest students knew their way around the basic mechanical tools, since some of those students grew up working on farms.

The Mast will certainly serve engineering students well, but other departments are making their way down to Meyer to take advantage of The Mast. Studio art students use mechanical tools for engraving or embossing pieces they’re working on. The Mathematics Department will use the 3D printer to demonstrate equations. Even nursing students make use of the lab.

“We are not trying to serve just students in our department, but students all over campus,” said Sang. He also noted that it’s good for students of different disciplines to work side by side and exchange ideas. The collaboration fosters a liberal arts mindset—that the majors are not isolated from one another, but are interconnected in ways that students might not expect.

Many students who are not in engineering would never have the occasion to visit the lower level of Meyer. Now, they have that opportunity.

As for the engineering program as a whole, it is only trending upward. Their current employment rate is 100%, with engineering alumni finding jobs in their specific field. As of this year, they have around 45 engineering majors.

With The Mast further legitimizing Bethany’s engineering program and professors facilitating hands-on, practical learning, interest in engineering sciences is sure to grow in the coming years.